Labels 48h to nowa linia etykiet

chatrakteryzujących się specjalnymi

rozwiązaniami oraz szybką realizacją

Design & Printing Specifications

Please, send your data that are to be printed as one of the following files: PDF, TIFF, JPEG or EPS. You may also send your data in the CDR file format.

Please, be patient – transmission may take some time depending on the size of your data. You should keep in mind that the maximum size of the file to be sent is 20 MB.

|

LEGEND:

2.SAFE DISTANCE 3.BLEEDS 4.OPERATING SPACE |

BOOKLET LABELS

- the die: if your label must be equipped with an opening grip, please, indicate the appropriate chosen parameters

- the safe distance: 2 mm

- the bleeds: 2 mm

- for the curves and other important elements within the page you should keep the minimum distance of 2 mm from the die

You should use only high-resolution images, depending on the image size, at least 300 dpi. Any images of lower DPI resolution, for example, pictures from the Internet, will not be clearly printed and they may appear blurry when printed.

SANDWICH LABELS

- the standard die with 2 mm radius of the corner

- the safe distance: 2 mm

- the bleeds: 2 mm

- for the curves and other important elements within the page you should keep the minimum distance of 2 mm from the die

You should use only high-resolution images, depending on the image size, at least 300 dpi. Any images of lower DPI resolution, for example, pictures from the Internet, will not be clearly printed and they may appear blurry when printed.

LABELS WITH BACK PRINTING

- the standard die with 2 mm radius of the corner

- the safe distance: 2 mm

- the bleeds: 2 mm

- for the curves and other important elements within the page you should keep the minimum distance of 2 mm from the die

You should use only high-resolution images, depending on the image size, at least 300 dpi. Any images of lower DPI resolution, for example, pictures from the Internet, will not be clearly printed and they may appear blurry when printed.

BLANKO LABELS

- the standard die with 2 mm radius of the corner

- the safe distance: 2 mm

- the bleeds: 2 mm

- for the curves and other important elements within the page you should keep the minimum distance of 2 mm from the die

You should use only high-resolution images, depending on the image size, at least 300 dpi. Any images of lower DPI resolution, for example, pictures from the Internet, will not be clearly printed and they may appear blurry when printed.

LABELS FOR FOODSTUFFS

- the standard die with 2 mm radius of the corner

- the safe distance: 2 mm

- the bleeds: 2 mm

- for the curves and other important elements within the page you should keep the minimum distance of 2 mm from the die

You should use only high-resolution images, depending on the image size, at least 300 dpi. Any images of lower DPI resolution, for example, pictures from the Internet, will not be clearly printed and they may appear blurry when printed.

The following graphics providing some additional information should make the ordering procedure easier for you.

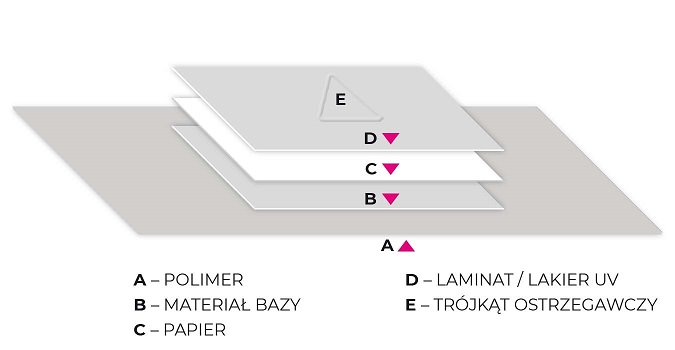

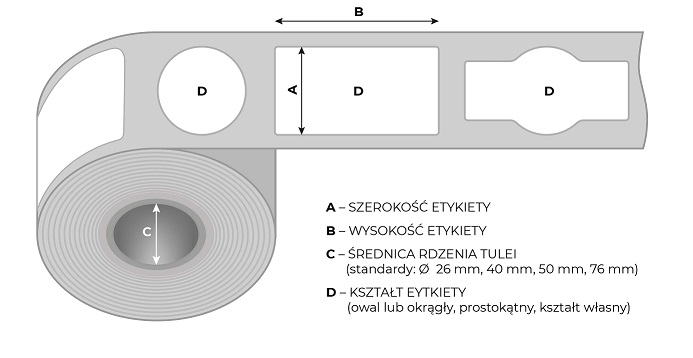

SCHEMAT ETYKIETY

A- POLYMER

This parameter is the base film that constitute the base of a label. It has significantly higher durability than self-adhesive film. It is very flexible so it perfectly adapts to the surface.

B-C BASE MTERIAL / PAPER

This parameter means some base layer of a label – you may choose between a paper label and a film label.

THE LABEL WITH THE PAPER BASE LAYER

We recommend using the paper labels mainly indoors, in dry conditions. If your labels are to be used outdoors, we recommend that you additionally choose the laminate to protect the labels against smudging, scratching and to increase their resistance to the environmental influence. We have a wide range of papers constituting the base material in the following versions: matte or glossy, and many variants of adhesives. Below we present examples of the paper:

- matte paper,

- glossy paper,

- ‘Termo Top’ thermal paper (such labels are used mainly for frozen products)

- silver/gold metallized paper (such labels are often used in promotion and advertising, their decorative effect is very similar to the embossed foil but it is much cheaper for the customer),

- fluorescent paper (available in many color versions: green / red / orange / yellow),

- Inkjet paper (for the labels designed for water-based Inkjet printing).

THE LABEL WITH THE FILM BASE LAYER

We recommend using these labels outdoors – the labels are resistant to any dirt and chemicals. The additional advantage of this label group is their water-resistance and resistance to smudging. We offer several types of the film. For example, PE film (made of polyethylene) is highly suitable for both indoor and outdoor applications. The polyethylene film is a stretchable material and it is well suited for both flexible containers and squeezable containers. Polyethylene plastic is characterized by low UV-resistance. So, we recommend that the labels should not be exposed to direct sunlight for a long period of time.

The second type of the base material is PP film (made of polypropylene). This material is also well suited for both indoor and outdoor applications. It is characterized by high resistance to weather conditions. The polypropylene plastic is highly durable and it performs well in labelling rigid and round containers.

Still another material is PVC film. This material is even more resistant to environmental factors. This plastic is characterized by resistance to both low and high temperature, to dirt, oils and fats, and chemicals. Polyvinyl chloride is a flexible and durable material.

What should you consider when you choose a base material for your label?

STORAGE > what weather conditions will the label be exposed to?

PROCESSING > temperature resistance – taking into account the forecast storage of the labelled product in future, assumptions of the sector of the market/industry.

CONTAINER > place where the label will be applied, rigidity, flexibility.

TRANSPORT > how will the label be delivered? Is it possible that the carrier will put it in danger of being scratched, contacting sea water, etc.?

You don’t know what adhesive you should choose? See our ranking of the adhesive strength!

Miejsce 1.Klej permanentny (odznaczający się dobrą wytrzymałością wewnętrzną i przyczepnością początkową na trudnych i apolarnych podłożach- PE, PP)

Miejsce 2.Klej akrylowy (modyfikowany klej odznaczający się dobrą przyczepnością do wielu różnych materiałów, w tym podłoży typu: PE i PP)

Miejsce 3.Klej usuwalny (klej przeznaczony głównie do powierzchni typu papier biały, matowy, błyszczący. Przyczepność kleju do powierzchni jest niska, znacznie większa w przypadku podłoża foliowego, daje to jednak możliwość całkowitego usunięcia warstwy kleju bez uszkodzenia zawartości etykiety).

In majority of our labels you may choose the number of printed pages, numbering options, label opening and the following colour variations:

1 COLOUR - BLACK

1 COLOUR

2 COLOURS

3 COLOURS

4 COLOURS

4 EUROSCALE COLOURS

4 EUROSCALE COLOURS + WHITE

4 EUROSCALE COLOURS + SPECIAL COLOUR

4 EUROSCALE COLOURS + SPECIAL COLOUR + WHITE

D LAMINATE/ UV VARNISH

Laminate provides a protective coating for the label content. We offer two versions of the laminate thickness for you to choose from: 0,025 mm and 0,03 mm. An alternative to laminate is UV varnish that also provides a protective function. It is available in two versions: glossy or matte.

E THE WARNING TRIANGLE

We offer the possibility of putting the warning triangle marking on your label, available in two sizes: 9 mm and 18 mm. This marking is designed for the group of visually impaired persons. Just recently we have implemented an innovative method that we offer to you – possibility of putting a warning triangle on your label in the form of direct print.

WYMIARY:

We are able to provide you with labels in any selected size. The maximum width of your label may be 280 mm, the maximum height of your label may be 360 mm. We can produce labels in any shape chosen by you. We offer 4 core diameters for you to choose from – 26 mm, 40 mm, 50 mm, 76 mm.

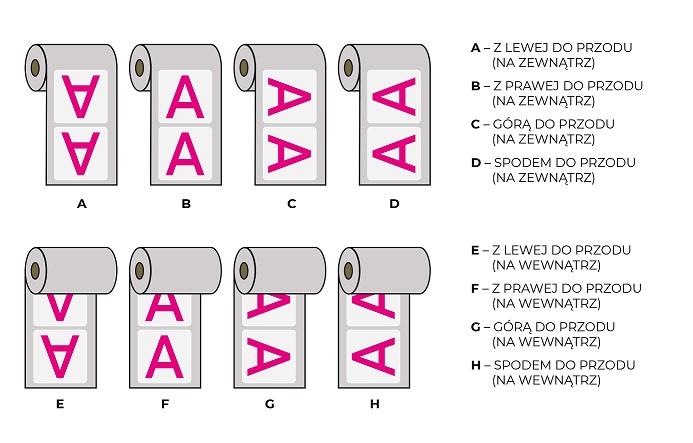

LABEL WINDING DIRECTION:

If you are unsure about the label winding direction, please, find below the visualization of our selection of the available parameters.

A – LEFT EDGE FIRST (OUTSIDE WOUND)

B – RIGHT EDGE FIRST (OUTSIDE WOUND)

C – HEAD FIRST (OUTSIDE WOUND)

D – FOOT FIRST (OUTSIDE WOUND)

E – LEFT EDGE FIRST (INSIDE WOUND)

F – RIGHT EDGE FIRST (INSIDE WOUND)

G – HEAD FIRST (INSIDE WOUND)

H – FOOT FIRST (INSIDE WOUND)